- Welcome to Foshan Chaosheng Automation Equipment Co.,Ltd.

-

Sitemap

Enquiry|

English|

Mail Us: shundecs@163.com|

Sitemap

Enquiry|

English|

Mail Us: shundecs@163.com|

Sitemap

Enquiry|

English|

Sitemap

Enquiry|

English|

*The

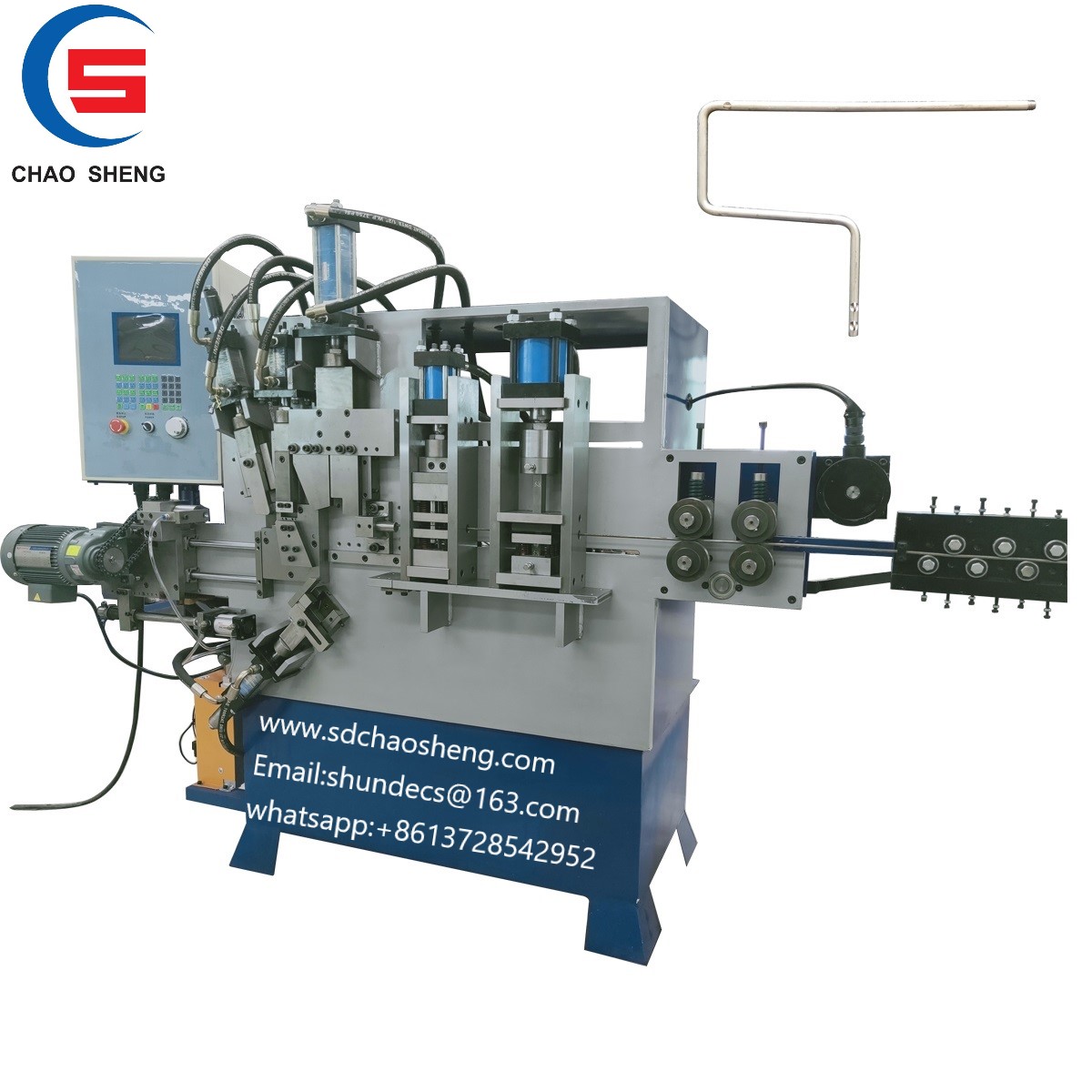

automatic paint roller handle bending machine has the following functions:

automatic straightening - cutting - ear - flattening - chamfering - tooth

rubbing - bending - finished products, etc. multiple processes are formed at

one time, which solves the complicated processes of traditional multiple semi-automatic

equipment, saving labor and energy.

The

processing accuracy of the equipment is 0.1mm and the yield is high.

*- the

equipment adopts thickened body, which is firm, stable and has a long service

life

*One

machine with multiple functions saves cost and time: iron wires of different

sizes and diameters can share a set of equipment by replacing hardware molds.

*A

single machine only needs one person to add materials and transfer finished

products in real time, which greatly saves manpower.

Technical

Data:

| Item No. | CS-8813L-ZWJ |

| Function | threading and charmfering type |

| wire size: | Ø3.0-8.0mm |

| Max Feeding length: | 0-500mm |

| Production capacity: | 720~1020pcs/H |

| MOTOR POWER | 5.5kw |

|

Machine size: |

2100x1150x1960mm |

| Packing size:(LxWxH) | 230 x127x192cm |

| G.W | 1350kg |